MIEBRS provides consultancy services on trouble shooting for dysfunctionality of effluent treatment plant (ETP) and sewage treatment plant (STP) by thorough adequacy study, design review, performance monitoring, functionality of accessories, study the effectiveness of the microbes and treatment chemicals applied. We have full-fledged laboratory facility for carrying out R&D study on biodegradation of hazardous industrial effluents. Our case studies include biodegradation of different types of hazardous effluent water with initial COD (chemical oxygen demand) range of 10,000 – 18,000 mg/l within very short time i.e. within 24 to 48 hrs. In all the cases the COD of the treated water complied with the permissible disposal standards of the federal regulatory authorities. We also provide consultancy on design and development of new ETPs and STPs for different types of industries including especially the vehicle service stations.

Some of our successful case studies in industrial effluent water treatment and sewage treatment include:

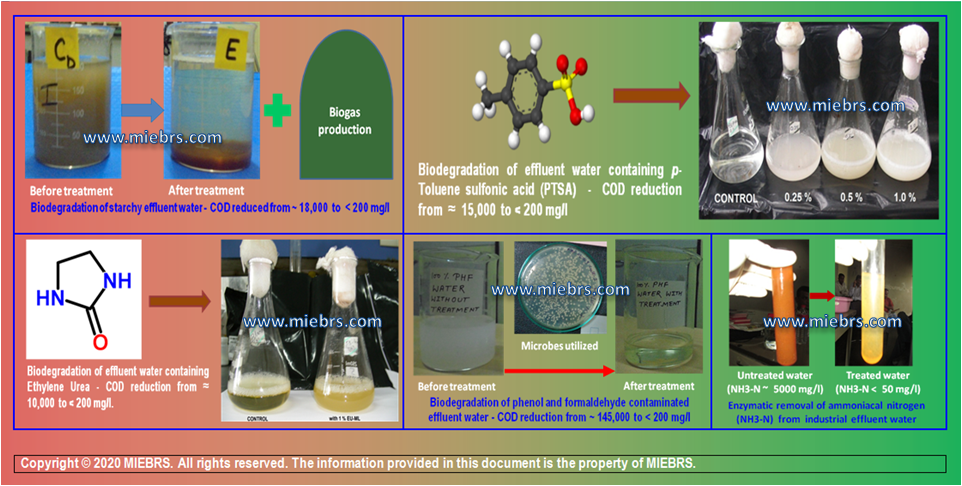

- Biodegradation of alkyl aryl sulfonic acid and its derivatives (initial COD ≈ 15,000 mg/l)

- Biodegradation of imidazolidones and its derivatives (initial COD ≈ 10,000 mg/l)

- Enzymatic removal of ammoniacal nitrogen from effluent water of dye and salt industries.

- Water Balance & ETP Adequacy study for one food industry and guidance for improvements.

- Biodegradation of 110 KLD liquid starchy effluents (initial COD ≈ 18,000 mg/l).

- Biodegradation of 10 KLD effluent water containing phenol and formaldehyde (initial COD ≈ 146,000 mg/l).

- Biodegradation of 50 KLD domestic sewage using DAF process

- Biogas production from 110 KLD liquid effluents containing starchy waste.

- Biodegradation of 425 KLD domestic sewage using MBBR process

- Design of 10 KLD STP with MBBR process.